Know More Details About Heat Press Machine

Heat transfer is a popular process, the emergence of digital technology and personalized consumer ideas, so that the application of thermal transfer technology more popular and extensive, application products after another, covering almost all areas of materials. Such as: metal, wood, stone, ceramics, glass, PVC, leather and so on ...

There are three types of heat transfer machines that are commonly used in the market:

1. More for personalized custom flat hot press;

2. Continuous thermal transfer machine for large printing and dyeing enterprises (roller type heat transfer machine);

3. Vacuum transfer printing machine.

Advantages and Defects of Heat Transfer Printing

Heat transfer printing in the pure polyester fabric on the best results, polyester-cotton blended fabric on the cotton fiber is not dispersed by the dye color, color than pure polyester fabric shallow, large surface of the flower-shaped flowers and white (white) phenomenon The

6 advantages:

(1) basic without water, less sewage;

(2) the process is short, India is finished;

(3) fine pattern, rich and clear level, artistic high, three-dimensional sense of strong, for the general method of printing less than, and can print photography and painting style of the pattern;

(4) printing colorful, in the sublimation process, the dye in the tar is left on the transfer paper, will not contaminate the fabric;

(5) the high rate of genuine, transfer can be printed once more sets of color patterns and no flowers;

(6) flexibility, the customer selected after the flowers can be printed in a short period of time out.

Pure nylon fabric can also heat transfer printing, but the color is low, wet treatment fastness is poor. Heat transfer printing method for the transfer of paper for the fabric length of 2 times, waste paper and post-printing residual dye is difficult to recover, and the printing of dark color is difficult, it is more used in some fabrics such as silk fabrics and knitted fabrics for local printing, and Some decorative printing.

Heat transfer printing of three machines

1 Flat heat press machine

Simple models for the top hot plate to maintain 180 ~ 220 ℃, the bottom of the plate by the non-heating support the printing parts and paper pressed against the top hot plate. Hot plate heating to transfer the dye on the paper to the fabric in close contact with it, the simple lifting action of the hot iron plate and paper contact goods to leave. To slip between paper and clothing or fabric, or prone to ghosting or smear.

There is a machine with a conveyor belt or feeding device, the top of the iron plate to do the vertical action, the bottom plate is heated, the paper on the conveyor belt, the surface up, the fabric on the paper to the printing site after the heat transfer, the upper iron Plate for the liner, according to the requirements of time feeding and loading.

Flat plate hot press operation is not continuous, the plate can be hot oil, electric or superheated steam heating. Heat transfer time by 15 ~ 60s calculation, about 50 to 100 per hour printing action.

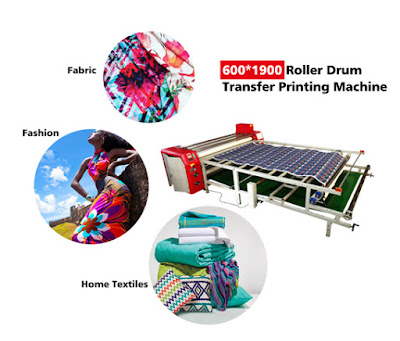

2 Roller heat press machine

The most common one is that the front of the fabric is in contact with the front of the paper and surrounds the surface of a heated roller with a seamless, blanking of the paper, the fabric and the surface of the heating roller, and a layer between the fabric and the blanket Backing paper to prevent tipping, the backing paper can be full, or only on both sides of the fabric.

In addition to the sufficient strength of the recycled blanket material, but also requires insulation, the glass transition temperature of 275 ℃ softening point above 350 ℃, this structure of the blanket heat resistance is better, it can be extended in the transfer printing temperature life The

This method of printing requires a uniform temperature on the surface of the heating drum to avoid changes in color along the cloth, which is difficult to achieve by conventional internal heating. The improvement is to use a hollow drum with a housing, Such as biphenyl and diphenyl ether mixture, the body after the exhaust air, immediately sealed the drum, heated to the carrier boiling, the steam condensed on the inner surface, the release of condensation heat, providing uniform high temperature heat transfer to ensure uniform surface of the drum.

3 Vacuum heat press machine

Both the plate hot press and the drum type printing machine can be operated under partial or full vacuum conditions. As long as an excellent perforated drum is used, the internal pressure can be made lower than the atmospheric pressure, passing the air through the printing paper and the fabric, Permeability to increase dye transfer rate. At the same time the fabric is sucked by the surface of the drum, and the drum close, due to internal and external pressure differences, without the need for blankets in the case, you can ensure that the fabric and paper have good contact, such as Kammegiesser Vacumat printing machine, infrared heater around the drum, from External supply of heat.

Through a porous metal belt or screen in full contact with the fabric, transferring the printed paper and the fabric to the heated surface of the roller press. This machine uses springs instead of blankets. Transfer printing paper, fabric and elastic band to form a vacuum chamber around the circumference of the drum continuously evacuated, vacuum chamber inlet and outlet with a sealed control to keep the low pressure.

This is the three types of hot press, respectively, to meet the requirements of different printing transfer, transfer properly will have a good thermal transfer effect.

There are three types of heat transfer machines that are commonly used in the market:

1. More for personalized custom flat hot press;

2. Continuous thermal transfer machine for large printing and dyeing enterprises (roller type heat transfer machine);

3. Vacuum transfer printing machine.

Advantages and Defects of Heat Transfer Printing

Heat transfer printing in the pure polyester fabric on the best results, polyester-cotton blended fabric on the cotton fiber is not dispersed by the dye color, color than pure polyester fabric shallow, large surface of the flower-shaped flowers and white (white) phenomenon The

6 advantages:

(1) basic without water, less sewage;

(2) the process is short, India is finished;

(3) fine pattern, rich and clear level, artistic high, three-dimensional sense of strong, for the general method of printing less than, and can print photography and painting style of the pattern;

(4) printing colorful, in the sublimation process, the dye in the tar is left on the transfer paper, will not contaminate the fabric;

(5) the high rate of genuine, transfer can be printed once more sets of color patterns and no flowers;

(6) flexibility, the customer selected after the flowers can be printed in a short period of time out.

Pure nylon fabric can also heat transfer printing, but the color is low, wet treatment fastness is poor. Heat transfer printing method for the transfer of paper for the fabric length of 2 times, waste paper and post-printing residual dye is difficult to recover, and the printing of dark color is difficult, it is more used in some fabrics such as silk fabrics and knitted fabrics for local printing, and Some decorative printing.

Heat transfer printing of three machines

1 Flat heat press machine

Simple models for the top hot plate to maintain 180 ~ 220 ℃, the bottom of the plate by the non-heating support the printing parts and paper pressed against the top hot plate. Hot plate heating to transfer the dye on the paper to the fabric in close contact with it, the simple lifting action of the hot iron plate and paper contact goods to leave. To slip between paper and clothing or fabric, or prone to ghosting or smear.

There is a machine with a conveyor belt or feeding device, the top of the iron plate to do the vertical action, the bottom plate is heated, the paper on the conveyor belt, the surface up, the fabric on the paper to the printing site after the heat transfer, the upper iron Plate for the liner, according to the requirements of time feeding and loading.

Flat plate hot press operation is not continuous, the plate can be hot oil, electric or superheated steam heating. Heat transfer time by 15 ~ 60s calculation, about 50 to 100 per hour printing action.

2 Roller heat press machine

The most common one is that the front of the fabric is in contact with the front of the paper and surrounds the surface of a heated roller with a seamless, blanking of the paper, the fabric and the surface of the heating roller, and a layer between the fabric and the blanket Backing paper to prevent tipping, the backing paper can be full, or only on both sides of the fabric.

In addition to the sufficient strength of the recycled blanket material, but also requires insulation, the glass transition temperature of 275 ℃ softening point above 350 ℃, this structure of the blanket heat resistance is better, it can be extended in the transfer printing temperature life The

This method of printing requires a uniform temperature on the surface of the heating drum to avoid changes in color along the cloth, which is difficult to achieve by conventional internal heating. The improvement is to use a hollow drum with a housing, Such as biphenyl and diphenyl ether mixture, the body after the exhaust air, immediately sealed the drum, heated to the carrier boiling, the steam condensed on the inner surface, the release of condensation heat, providing uniform high temperature heat transfer to ensure uniform surface of the drum.

3 Vacuum heat press machine

Both the plate hot press and the drum type printing machine can be operated under partial or full vacuum conditions. As long as an excellent perforated drum is used, the internal pressure can be made lower than the atmospheric pressure, passing the air through the printing paper and the fabric, Permeability to increase dye transfer rate. At the same time the fabric is sucked by the surface of the drum, and the drum close, due to internal and external pressure differences, without the need for blankets in the case, you can ensure that the fabric and paper have good contact, such as Kammegiesser Vacumat printing machine, infrared heater around the drum, from External supply of heat.

Through a porous metal belt or screen in full contact with the fabric, transferring the printed paper and the fabric to the heated surface of the roller press. This machine uses springs instead of blankets. Transfer printing paper, fabric and elastic band to form a vacuum chamber around the circumference of the drum continuously evacuated, vacuum chamber inlet and outlet with a sealed control to keep the low pressure.

This is the three types of hot press, respectively, to meet the requirements of different printing transfer, transfer properly will have a good thermal transfer effect.

Welcome to contract us !

Company:nanjing hi transfer digital technology co.,limited

website:http://hitransfer.com/index.php

facebook:https://www.facebook.com/techsublimation

twitter:https://twitter.com/techsublimation

linkedin:https://www.linkedin.com/in/tech-sublimation-548a7a133/

google+:https://plus.google.com/u/0/107910599828124340419

vk:https://vk.com/sbpaper

whatsapp:+8615756007679

Company:nanjing hi transfer digital technology co.,limited

website:http://hitransfer.com/index.php

facebook:https://www.facebook.com/techsublimation

twitter:https://twitter.com/techsublimation

linkedin:https://www.linkedin.com/in/tech-sublimation-548a7a133/

google+:https://plus.google.com/u/0/107910599828124340419

vk:https://vk.com/sbpaper

whatsapp:+8615756007679

评论

发表评论