Heat transfer ink - the "blood" of heat transfer

As the name of fashion and personality printing technology, digital thermal transfer has undoubtedly received a lot of attention and favor. And its "blood" ink is the fastest and most expensive consumable. It is important to know more about ink and to print better images for us.

Composition of heat transfer ink:

The ink is usually composed of a solvent, a colorant, a surfactant, a pH adjuster, a drier, and other essential additives. Among them, the solvent accounts for the largest proportion of ink in inkjet printers and is the main component. The performance of the colorant directly affects the color and hue of the printed image, and its own color, mixing performance, solubility, acidity and alkalinity, and particle size are particularly important.Main performance parameters of heat transfer ink:

Viscosity and surface tension: Viscosity is the resistance of liquid flow, and the surface tension of liquid is related to the ability to form droplets. In general, inkjet inks have a low viscosity and high surface tension to ensure good flow properties and droplet morphology.PH value: It means the concept of liquid pH. The more acidic the solution, the lower the PH value. Conversely, the more alkali the solution, the higher the PH value. To prevent ink from eroding the nozzle, the pH should generally be between 7 and 12.

Conductivity: In the ink, the conductivity value is used to reflect the level of salt content. In general, the salt content should not exceed 0.5% to avoid clogging due to crystal formation in the nozzle.

Dispersant: A kind of surfactant. Its main function is to improve the physical properties of the ink surface and enhance the affinity and wettability of the ink and the sponge. Therefore, the ink which is generally stored and transmitted through the sponge contains a dispersing agent.

Choose the best quality materials and check the above parameters. Nanjing Feiyue Paper Co., Ltd. has introduced the following high-quality inks, each with its own characteristics, I believe it will be your first choice.

Advantages of thermal transfer ink:

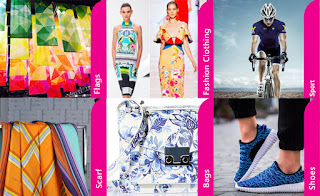

It is suitable for digital printing of polyester fabrics and hard materials coated with polyester coating.It is suitable for micro-piezoelectric printing digital printers with high printing precision and long nozzle life.

The use of international top ink, smooth and fast-drying, colorful saturation, high color fastness, in line with European and American environmental standards.

With professional thermal transfer paper, the shape is sufficient, the wet heat deformation rate is low, and it meets higher precision.

RIP software with built-in dedicated color management system guarantees printing effect.

Auxiliary technical support and after-sales service to solve worries.

评论

发表评论