The difference between digital printing and traditional printing

Dry goods: the difference between digital printing and traditional printing

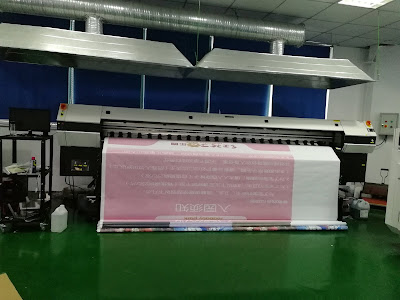

With the emergence of digital printing, the traditional printing industry has been greatly impacted. What's the difference between them? The production process of digital printing is to use various modern digital equipment to process and produce various digital patterns. After being processed by the computer color separation software, Rip (print output software) of the special door will process various special dyes (active, acid and disperse) through its printing system , coating) directly sublimation printing on the treated corresponding fabric or other media, and then process the fabric in the later stage to form colorful and colorful patterns.

So let's talk about the comparison between digital printing and traditional printing?

1. The whole process of digital printing is digitized, so that the design and production of printed products can not only quickly respond to their order requirements, but also have a great deal of randomness. Flexible production can be carried out according to needs. Satisfied. The use of traditional printing requires color separation, screen making, color matching, pulp mixing, printing, post-processing and other processes that take a long time and have a large production cost, and customers are not necessarily satisfied.

2. The design draft can be arbitrarily modified on the computer, and the designer's design ideas and aesthetic concepts can be fully and fully displayed. If the designer is not satisfied with the proofing effect, he can immediately modify it in the computer, and after several color preparations and pattern changes, until the satisfactory effect is achieved. In traditional printing, once the designer's sample is determined, it is difficult to perform secondary creation and modification. For patterns, patterns, color matching, etc., they lack flexibility and rapid market adaptability in production.

3. Digital printing technology uses digitally controlled nozzles to spray the corresponding dyeing liquid dots as needed on the part where the dye is needed. Many tiny dots quickly form the required pattern to achieve visually consistent color and realistic pattern. The traditional printing has relatively poor performance of color saturation and gradation, and it is also difficult to grasp the excessive moire.

4. Due to the high printing accuracy of the digital printing machine, there are almost no problems with the accuracy of flower registration and color registration. No matter what pattern and how many types of color registration, the direct printing method is used. It avoids the contamination of a large amount of reducing agents and waste of dyes in the traditional "engraving" process, and also guarantees bright color light and fastness.

More info:

Tel: 86-025-83228884

Whatsapp: +86 18851084450

Website:www.ink-sublimation.com

E-mail: janezhang940213@gmail.com

Facebook:www.facebook.com/burberry.chen.1

评论

发表评论