Precautions when replacing the printhead of a digital inkjet printer

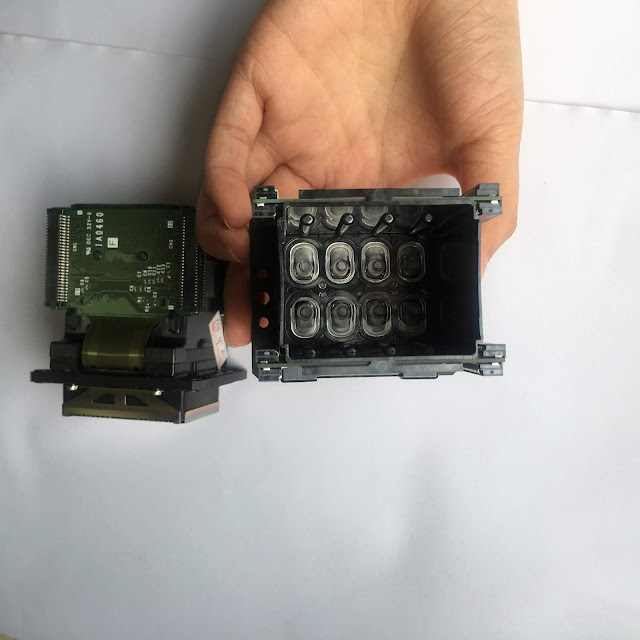

The print head replacement precautions, the photo head of the digital inkjet printer is an important part of the photo machine. Sometimes you need to replace the print head. When you replace the print head, you must pay attention to the correct replacement operation mode. Otherwise, it is easy to cause the newly replaced print head to be blocked or even scrapped.

The human body itself is the largest electrostatic carrier. When replacing the print head, you should pay attention to the static electricity that you bring, otherwise it will be easy to burn the nozzle circuit when replacing. The new print head must be filled with 20ml-25ml ink before use. The speed during the filling process should not be too fast. Otherwise, it will easily cause a large amount of air bubbles in the ink to prevent the ink from flowing into the ejection chamber, so that the heating element in the print head cannot be cooled normally and burned. Nozzle (optional larger injection is optional). After the ink is filled, the ink is drawn out of the pipe to prevent the ink from flowing back. Then, the printer print head is installed, and then the air in the nozzle is drained by the ink absorber, and the ink on the print head is wiped off. ink. If there is ink outside the print head, it may cause a short circuit in the circuit behind the print head. If the air is not drained in the pipe, the nozzle will be burnt and the service life of the nozzle will be affected.

When the user is handling the ink head, the force of the ink is not too large, but the syringe is gently pulled. Then loosen, the ink head is higher than the syringe, so that the ink slowly flows into the heating chamber of the ink head, and the air in the heating chamber is removed. This ensures that there is no negative pressure in the heated head of the ink head, and the ink can be smoothly sprayed onto the screen.

Before you work, be sure to check the contacts behind the ink head for ink drops. If there are ink drops, there will be a regular broken needle when spraying the picture, and even affect the other three good ink heads. Therefore, everyone must pay attention to the phenomenon: to ensure that the contact cable is clean, do not make ink on the contacts of the contact cable. If there is ink, it will cause the above phenomenon, you can wipe it with paper in the case of shutdown.

1. When there is a lot of business, it is best to remove the ink head from the machine every day (about 8 hours), use a soft cloth or paper towel that can not use fiber or paper scraps, clean the bottom of the print head with pure water, use alcohol Wipe the side of the ink head and the contact chip (do not wipe the print head nozzle, only flick). This operation needs to be performed at shutdown and cannot be turned on immediately after the operation.

2. Since the machine on the far right side of the machine will often scrape off the ink on the print head during work, flush or replace the cleaning box after a period of use.

3. Air treatment in the ink path Check the ink interface and seal with glue if necessary. After the ink head is mounted, the silicone is applied to the seam of the ink needle and the ink head.

More info:

Tel: 86-025-83228884

Whatsapp: +86 18851084450

Website:www.ink-sublimation.com

E-mail: janezhang940213@gmail.com

Facebook:www.facebook.com/burberry.chen.1

1. Print head replacement method

The human body itself is the largest electrostatic carrier. When replacing the print head, you should pay attention to the static electricity that you bring, otherwise it will be easy to burn the nozzle circuit when replacing. The new print head must be filled with 20ml-25ml ink before use. The speed during the filling process should not be too fast. Otherwise, it will easily cause a large amount of air bubbles in the ink to prevent the ink from flowing into the ejection chamber, so that the heating element in the print head cannot be cooled normally and burned. Nozzle (optional larger injection is optional). After the ink is filled, the ink is drawn out of the pipe to prevent the ink from flowing back. Then, the printer print head is installed, and then the air in the nozzle is drained by the ink absorber, and the ink on the print head is wiped off. ink. If there is ink outside the print head, it may cause a short circuit in the circuit behind the print head. If the air is not drained in the pipe, the nozzle will be burnt and the service life of the nozzle will be affected.

2. The ink extraction method of the print head

When the user is handling the ink head, the force of the ink is not too large, but the syringe is gently pulled. Then loosen, the ink head is higher than the syringe, so that the ink slowly flows into the heating chamber of the ink head, and the air in the heating chamber is removed. This ensures that there is no negative pressure in the heated head of the ink head, and the ink can be smoothly sprayed onto the screen.

3. Ensure the cleaning of the back of the ink head

Before you work, be sure to check the contacts behind the ink head for ink drops. If there are ink drops, there will be a regular broken needle when spraying the picture, and even affect the other three good ink heads. Therefore, everyone must pay attention to the phenomenon: to ensure that the contact cable is clean, do not make ink on the contacts of the contact cable. If there is ink, it will cause the above phenomenon, you can wipe it with paper in the case of shutdown.

Read more: nozzle maintenance of digital inkjet printer

1. When there is a lot of business, it is best to remove the ink head from the machine every day (about 8 hours), use a soft cloth or paper towel that can not use fiber or paper scraps, clean the bottom of the print head with pure water, use alcohol Wipe the side of the ink head and the contact chip (do not wipe the print head nozzle, only flick). This operation needs to be performed at shutdown and cannot be turned on immediately after the operation.

2. Since the machine on the far right side of the machine will often scrape off the ink on the print head during work, flush or replace the cleaning box after a period of use.

3. Air treatment in the ink path Check the ink interface and seal with glue if necessary. After the ink head is mounted, the silicone is applied to the seam of the ink needle and the ink head.

More info:

Tel: 86-025-83228884

Whatsapp: +86 18851084450

Website:www.ink-sublimation.com

E-mail: janezhang940213@gmail.com

Facebook:www.facebook.com/burberry.chen.1

评论

发表评论