The comparison of screen printing and thermal transfer printing

When it comes to

heat transfer printing, a lot of people don't know it, even the person of the

printing industry. But If mention screen printing and other printing, people in

packaging are much clear of it. Silk-screen printing has developed for many

years since the ancient of China. During more than thousands of years of development,

silk-screen printing is still used widely in a variety of products. In recent

20 years, heat transfer printing emerges in printing industry which is a new

printing technology, while developing rapidly for its good effeteness. The new

technology has its vitality and has its broad prospect. Right now, the ink

manufacturers is to guide consumers to use new technology, apply new and high

technology, improve the grade of products.Today, let us see

the difference between these two printing technology.

Screen printing

Screen printing is a kind of porous printing which forms the pattern onto substrates

through the pressure with transfer printing ink. Screen printing is simple, low-

cost which is suitable for color paintings, posters, business cards, book

covers, product tags, textiles etc. It is suitable for spot-color printing. In

terms of four color printing, it has price advantage, but emerging printing

technology--sublimation printing technology does better in printing result,like

the true colorful pattern,no-ghost,smooth- touch etc. In addition, in production,

screen printing is one color printing color showing poor production efficiency,

not good color gradient effect(thick ink).

Thermal transfer

printing ink is much thinner, while printing patterns is colorful gorgeously,

strong-adhesion, abrasion-resistance, and is suitable for mass production.Besides

clothing,textiles, It is also suitable for ABS, PS, PP, PE, EVA, PVC materials

such as plastic, metal, wood, leather and other products surface heat transfer.

At present it is mainly used in daily necessities, stationery, toys, electronic

products, gifts, building materials and other industries.

|

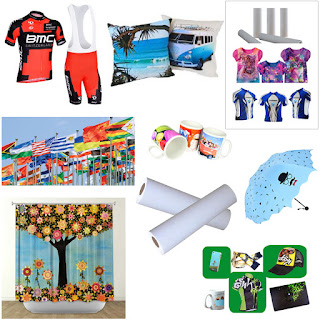

| sublimation stuff |

Thermal transferring

shows one-time multi-color printing in high efficacy. The patterns are printed

fine with good color gradient effect. As a new technology, the price is higher

than silk-screen printing, but it brings higher added- value of products. On

the printing effect, production efficiency has its obvious advantages. So,

there are a lot of potential in its applicable field and market.

In conclusion,

all kinds of printing works in the field have a certain advantage, how to

choose depends on materials, surface characteristics,etc. According to the

product cost, pattern effects, adhesion, do some trials,then choose the right

way for your business.

GetWin Industrial Co., LTD. is deal with sublimation transfer paper,t-shirt transfer paper, fast dry sublimation paper, dye sublimation ink, photo paper, heat press machine, ink chip, ink cartridge and large format printer.

*Information

Company: GetWin Industrial Co.,LTD

Website: www.ink-sublimation.com

E-mail:sales@ink-sublimation.com

Whatsapp: +008618196645969

-------------------

*FOLLOW ME

Facebook:https://www.facebook.com/techsublimation

Twitter: https://twitter.com/techsublimation

Google+ https://plus.google.com/u/0/

Pinterst https://www.pinterest.com/techsublimation/

Blogger:tech-sublimation.blogspot.com

inkjet-printer001.blogspot.com

评论

发表评论