Analyze the use of light color heat transfer paper

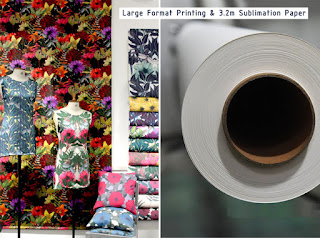

The heat transfer paper is capable of outputting the pattern to be stamped by an inkjet printer and printing it on the clothes. Mainly divided into light heat transfer paper and dark transfer paper. Light-colored transfer paper is suitable for printing white and other light-colored clothes; dark transfer paper is suitable for printing dark clothes such as black.

Also known as the summons paper. Used to make tram and bus tickets. Its characteristics are similar to mechanical wood pulp stickers, but the color range is wider. Quantitative above 100g/m2, excellent uniformity and thickness, high stiffness and appearance properties (such as smooth surface, fine). It was made from mechanical wood pulp on a fourdrinier paper machine.

Transfer paper can also be divided into metal transfer paper and pigment transfer paper. In a broad sense, it also includes coated paper produced by a heat-sensitive paint or a pressure-sensitive paint, and a paper coated with a wet transfer film, such as a lettering transfer film.

How to use sublimation transfer paper?This is a practical problem often encountered by novices in the operation process. Once the operation is not good, it will cost more than 10 yuan or even tens of dollars for the transfer paper of a few dollars. Other electricity charges and inks are also a kind of loss, and they will also form a kind of pressure in the heart, and even suspect the operability of this heat transfer method.

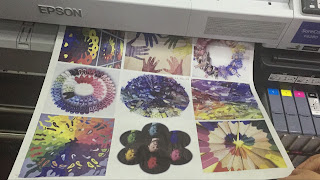

First of all, it is necessary to pass the selection on the transfer paper. This has already been said in other chapters and will not be repeated here. Select the transfer paper and adjust the image size you need in the image processing software. The next step is to print the pattern. The printed pattern must first be cut with scissors to remove the excess part without the print pattern, and then wait for the printing machine. When the temperature rises, the pattern can be transferred. (The printing temperature of the imported printing paper in the United States is 185 degrees - 190 degrees. The time should be determined according to the ink you use. If it is ordinary ink, it can be printed in 10-12 seconds. If it is a heat transfer ink, the printing time is longer. The recommended time is 25-30 seconds. If the time is long, the printing time can be determined according to the actual operating experience).

The tide of clothing is the first step in the printing process. The garments that need to transfer the pattern are pressed on the printing machine for 2-3 seconds, which can not only give the garment moisture, but also the clothing that needs to transfer the pattern. The quality of the printed pattern has been further improved, and the pressure of the printing machine can also be tested.

When the temperature of the machine rises, it can be printed. Place the pattern to be transferred on the garment where it needs to be printed, set the printing time and then press the printing machine. The time will be the buzzer of the printing machine. When it rings, then open the printing machine to tear off the pattern of the bottom paper, then pull the garment up and down, left and right, in order to enhance the breath ability of the printed part of the garment. Such a personalized costume is printed. Need to remind again that the US imported transfer paper is a hot-tear transfer paper. After opening the printing machine, the bottom paper should be removed in time. If the temperature is torn or cold-tear, it is the wrong operation method.

Also known as the summons paper. Used to make tram and bus tickets. Its characteristics are similar to mechanical wood pulp stickers, but the color range is wider. Quantitative above 100g/m2, excellent uniformity and thickness, high stiffness and appearance properties (such as smooth surface, fine). It was made from mechanical wood pulp on a fourdrinier paper machine.

Transfer paper can also be divided into metal transfer paper and pigment transfer paper. In a broad sense, it also includes coated paper produced by a heat-sensitive paint or a pressure-sensitive paint, and a paper coated with a wet transfer film, such as a lettering transfer film.

How to use sublimation transfer paper?This is a practical problem often encountered by novices in the operation process. Once the operation is not good, it will cost more than 10 yuan or even tens of dollars for the transfer paper of a few dollars. Other electricity charges and inks are also a kind of loss, and they will also form a kind of pressure in the heart, and even suspect the operability of this heat transfer method.

First of all, it is necessary to pass the selection on the transfer paper. This has already been said in other chapters and will not be repeated here. Select the transfer paper and adjust the image size you need in the image processing software. The next step is to print the pattern. The printed pattern must first be cut with scissors to remove the excess part without the print pattern, and then wait for the printing machine. When the temperature rises, the pattern can be transferred. (The printing temperature of the imported printing paper in the United States is 185 degrees - 190 degrees. The time should be determined according to the ink you use. If it is ordinary ink, it can be printed in 10-12 seconds. If it is a heat transfer ink, the printing time is longer. The recommended time is 25-30 seconds. If the time is long, the printing time can be determined according to the actual operating experience).

The tide of clothing is the first step in the printing process. The garments that need to transfer the pattern are pressed on the printing machine for 2-3 seconds, which can not only give the garment moisture, but also the clothing that needs to transfer the pattern. The quality of the printed pattern has been further improved, and the pressure of the printing machine can also be tested.

When the temperature of the machine rises, it can be printed. Place the pattern to be transferred on the garment where it needs to be printed, set the printing time and then press the printing machine. The time will be the buzzer of the printing machine. When it rings, then open the printing machine to tear off the pattern of the bottom paper, then pull the garment up and down, left and right, in order to enhance the breath ability of the printed part of the garment. Such a personalized costume is printed. Need to remind again that the US imported transfer paper is a hot-tear transfer paper. After opening the printing machine, the bottom paper should be removed in time. If the temperature is torn or cold-tear, it is the wrong operation method.

More info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 18851084450

Address: Central Road 323, Nanjing, Jiangsu, China

评论

发表评论