Construction principle and application industry of UV printer

Detailed explanation of the construction principle of UV printer and its application industry.

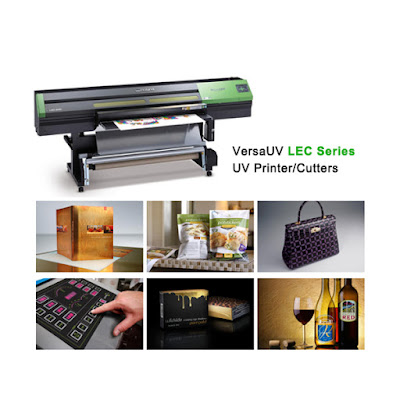

Digital printing refers to the control of fine ink flow through a computer, which is sprayed on a board through a nozzle, and the UV ink is cured by ultraviolet radiation, so that the image is displayed on the board. .

The pattern sprayed by this technology is bright and rich in color, abrasion resistance, UV resistance, simple and convenient operation, fast imaging speed, and greatly improved product productivity. These qualities fully meet the industry standards for the production of furniture and wood products.

Applying UV printing technology to flat printing in various industries can allow customers to have their favorite pattern effects and truly achieve personalization and customization. Compared with other printing methods, UV printing has lower cost and better effect.

The machine is mainly composed of two major systems: hardware and software. The hardware system is mainly divided into three parts: ink supply, inkjet, and mobile. The two parts of ink supply and inkjet are concentrated in the mobile printing device, which realizes the mobile function through the mute guide.

The software part mainly includes three parts: user setting system, RIP processing system (software that converts pictures, etc. into printable dot matrix data), and motion control system.

The core of UV digital inkjet printing technology is the RIP processing system. RIP is the abbreviation of Raster Image Processor, which refers to converting digital image information into raster dot matrix data to adapt to UV printing.

1.Environmental protection and safety

UV ink used in inkjet is environmentally friendly and safe. It will not produce any harmful substances during production and will not affect human health.

2.High efficiency

UV digital printing is not only suitable for small batch and personalized production, but also for large batch production. The machine can work continuously for a long time, and can replace manual or semi-automatic inkjet with low efficiency and low production capacity, which solves the problem of high cost and high inventory in the traditional production method.

3.Wide range of application

UV printer can print on a variety of materials, suitable for metal, glass, wood, plastic, acrylic and other materials, which enriches the unlimited possibilities of enterprise variety production.

More info:

Tel: 86-025-83228884

Whatsapp: https://wa.me/8618851084450

Website:www.ink-sublimation.com

E-mail: janezhang940213@gmail.com

Facebook:www.facebook.com/burberry.chen.1

What is UV digital printing

Digital printing refers to the control of fine ink flow through a computer, which is sprayed on a board through a nozzle, and the UV ink is cured by ultraviolet radiation, so that the image is displayed on the board. .

The pattern sprayed by this technology is bright and rich in color, abrasion resistance, UV resistance, simple and convenient operation, fast imaging speed, and greatly improved product productivity. These qualities fully meet the industry standards for the production of furniture and wood products.

Applying UV printing technology to flat printing in various industries can allow customers to have their favorite pattern effects and truly achieve personalization and customization. Compared with other printing methods, UV printing has lower cost and better effect.

Composition of UV printer

The machine is mainly composed of two major systems: hardware and software. The hardware system is mainly divided into three parts: ink supply, inkjet, and mobile. The two parts of ink supply and inkjet are concentrated in the mobile printing device, which realizes the mobile function through the mute guide.

The software part mainly includes three parts: user setting system, RIP processing system (software that converts pictures, etc. into printable dot matrix data), and motion control system.

The core of UV digital inkjet printing technology is the RIP processing system. RIP is the abbreviation of Raster Image Processor, which refers to converting digital image information into raster dot matrix data to adapt to UV printing.

What's so good about UV printer digital printing?

1.Environmental protection and safety

UV ink used in inkjet is environmentally friendly and safe. It will not produce any harmful substances during production and will not affect human health.

2.High efficiency

UV digital printing is not only suitable for small batch and personalized production, but also for large batch production. The machine can work continuously for a long time, and can replace manual or semi-automatic inkjet with low efficiency and low production capacity, which solves the problem of high cost and high inventory in the traditional production method.

3.Wide range of application

UV printer can print on a variety of materials, suitable for metal, glass, wood, plastic, acrylic and other materials, which enriches the unlimited possibilities of enterprise variety production.

More info:

Tel: 86-025-83228884

Whatsapp: https://wa.me/8618851084450

Website:www.ink-sublimation.com

E-mail: janezhang940213@gmail.com

Facebook:www.facebook.com/burberry.chen.1

Great tips, many thanks for sharing. I have printed and will stick on the wall! I like this blog. Custom t shirt transfers wholesale

回复删除